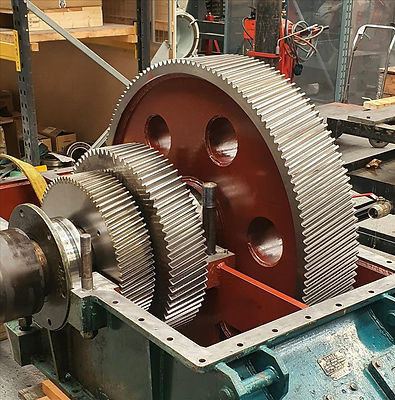

Gear Set Inspection

Fluorescent Magnetic Particle Inspection for Gear Sets

Fluorescent Magnetic Particle Inspection (MPI) is a precise non-destructive testing (NDT) technique used to identify surface and near-surface defects in ferromagnetic materials. This method is particularly effective for inspecting gear sets, ensuring their reliability by detecting cracks, inclusions, and other flaws before they lead to costly failures. Using fluorescent particles under ultraviolet (UV) light enhances defect visibility, making it an indispensable tool for maintaining high-performance components.

How We Perform Fluorescent MPI on Gear Sets

Our fluorescent MPI process includes the following steps to ensure thorough and reliable testing:

-

Surface Preparation: The gear set is cleaned to remove any dirt, grease, or debris that could obscure defects.

-

Magnetization: A magnetic field is applied to the gear set to align magnetic lines of force within the material.

-

Fluorescent Particle Application: Fine fluorescent magnetic particles are applied to the magnetized gear. These particles are drawn to areas where the magnetic field is disrupted, such as cracks or voids.

-

Inspection under UV Light: The gear set is examined under UV light, revealing defects as bright, glowing indications.

-

Evaluation: Our skilled inspectors analyze the indications to determine the size, location, and severity of any defects.

For added convenience, we use a portable inspection tent for mobile testing. This enables us to perform high-quality inspections at your site, ensuring minimal disruption to your operations while maintaining optimal testing conditions.

Why Test Sets with Fluorescent MPI?

-

Unmatched Precision: Fluorescent MPI provides exceptional clarity for detecting even the smallest defects.

-

Efficient Results: The process is fast and reliable, helping you avoid extended downtime.

-

Non-Damaging: As a non-intrusive method, fluorescent MPI preserves the integrity of your gear sets.

-

Cost Savings: Early defect detection reduces the risk of failure, saving on repairs and replacements.

-

Mobile Testing Capability: Our portable inspection tent allows us to bring advanced testing to your location.

Applications of Fluorescent MPI for Gear Sets

This technique is ideal for inspecting gear sets in various industries and applications, including:

-

Wind Turbines: Ensuring gearbox components remain reliable in renewable energy systems.

-

Industrial Machinery: Verifying the integrity of gears in manufacturing and processing equipment.

-

Extrusion Systems: Maintaining the performance of gears in extrusion machinery.

-

Energy Sector: Inspecting gears in turbines, generators, and related systems.

-

Aerospace and Defense: Testing gears in high-precision equipment where safety is critical.

-

Manufacturing: Quality assurance for new or refurbished gear sets.

Comprehensive Reporting

Every inspection is followed by a detailed report that includes:

-

A summary of the inspection process.

-

Documentation of any defects detected.

-

Recommendations for repair, replacement, or continued monitoring.

Our reports help you make informed decisions about maintenance, ensuring your gear sets operate safely and efficiently.

Our Skilled Team

At Testa, we bring years of experience and industry-recognized certifications to every inspection. Our team specializes in gear set testing, including mobile inspections with our portable tent. By inspecting gears during servicing, we help minimize downtime, reduce costs, and provide peace of mind. You can trust us to deliver accurate and reliable results, keeping your critical components in top condition.