Macro Examination

What is Macro Examination?

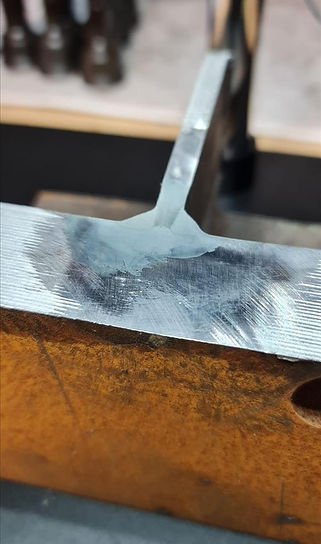

Macro examination is a vital non-destructive testing technique used to analyze the microstructure of materials. It enables the identification of defects and irregularities at a macro level, ensuring the integrity and reliability of components in various industries.

How Does Macro Examination Work?

The macro examination process involves several key steps:

-

Sample Preparation: The test sample is carefully prepared, often involving cutting, polishing, and etching to reveal the material's microstructure.

-

Inspection: The prepared sample is examined visually or under a microscope to detect any anomalies such as grain structure, inclusions, or other defects.

-

Documentation: Observations are meticulously recorded, providing a comprehensive overview of the sample's condition.

Advantages of Using Macro Examination

-

Detailed Analysis: Macro examination provides a thorough understanding of the material's microstructure, allowing for precise evaluations.

-

Non-Destructive: As a non-destructive method, macro examination does not compromise the integrity of the test sample, preserving its usability.

-

Versatile Applications: This technique can be applied to various materials, including metals, composites, and ceramics, making it suitable for multiple industries.

-

Expert Insight: Our experienced technicians provide valuable insights based on their findings, helping clients make informed decisions regarding material integrity.

Applications of Macro Examination

Macro examination is widely utilized across various industries, including, but not limited to:

-

Aerospace: To assess the quality of components such as aircraft frames and engine parts.

-

Oil & Gas: For the evaluation of pipeline materials and pressure vessels.

-

Manufacturing: To inspect welds, castings, and other fabricated components.

-

Construction: For the examination of structural materials, ensuring safety and compliance with regulations.

-

Power Generation: To analyze turbine and generator components, ensuring operational reliability.

Comprehensive Reporting

With every macro examination, we provide detailed written reports outlining our findings. These reports include a summary of the examination process, observed defects, and recommendations for further action, ensuring that you have a clear understanding of the material's condition.

Our Skilled Team

At Testa, our dedicated and skilled team is committed to delivering high-quality macro examination services. With extensive training and expertise in non-destructive testing techniques, our staff ensures that every examination is conducted thoroughly and accurately, adhering to the highest safety and reliability standards. All our technicians are qualified to industry-recognized PCN (Personnel Certification in Non-Destructive Testing) standards in accordance with BS EN ISO 9712.